Setting up a home workshop or studio is one of those projects that starts with excitement and big plans, then quickly runs into practical realities. Most people focus on space, layout, and equipment – all important stuff. But there’s one aspect that catches nearly everyone off guard: power. Not just having enough outlets, but whether the electrical system can actually handle what you’re planning to do.

This isn’t about being overly cautious or getting into complex technical details. It’s about avoiding the frustration of tripping breakers constantly, damaging expensive equipment, or realizing halfway through your setup that the whole plan needs rethinking.

What Most People Get Wrong About Power Needs

Walk into any home improvement store and you’ll find tools and equipment with their power requirements listed right on the box. Easy enough to understand, right? Just add them up and make sure you’ve got enough capacity.

Except it’s not quite that simple.

The problem is that those numbers don’t tell the whole story. Some equipment draws way more power when it starts up than when it’s running. A motor-driven tool might pull several times its running power for a few seconds during startup. Air compressors are particularly bad for this – they can spike hard enough to trip a breaker even when the circuit should technically handle them.

Then there’s the issue of what else is already on that circuit. Most home workshops share electrical circuits with other parts of the house. Your shed might be on the same circuit as outdoor lights and power points. Your garage workshop could share with the laundry or part of the house. Start running serious equipment and you’re not just competing with your own tools – you’re competing with whatever else someone might turn on.

The Reality of Standard Home Power

Most residential properties run on what’s called single-phase power. It’s the standard setup, works fine for normal household needs, and handles typical workshop equipment without issues. You can run power tools, a decent dust collection system, standard welders, and most hobby equipment without problems.

But here’s where it gets tricky. Single-phase systems have limits, and some equipment pushes right up against those limits or exceeds them entirely. Large table saws, industrial dust collectors, bigger air compressors, and commercial-grade equipment often prefer or require different power configurations. This is especially true if you’re planning to run multiple pieces of heavy equipment at once.

Understanding the difference between single phase vs three phase power becomes important when you’re serious about your workshop setup. Three-phase systems can handle higher loads more efficiently and run heavy equipment more smoothly, but they’re not standard in residential properties and require specific electrical work to install.

When Standard Power Works Fine

Before assuming you need major electrical work, it’s worth understanding what actually works well with standard residential power. The reality is that most home workshops operate perfectly fine without upgrades.

Standard woodworking tools – even quality cabinet saws, routers, planers, and joiners – typically run on single-phase power without issues. Most welders designed for home use work fine on standard circuits. Reasonable-sized air compressors generally don’t cause problems. Dust collection systems, CNC machines for hobbyists, 3D printers, pottery wheels, and most studio equipment all run happily on regular household power.

The key is understanding your actual usage patterns. If you’re running one tool at a time, taking breaks between operations, and not pushing equipment to its limits constantly, standard power handles it. Most hobbyists and even serious home woodworkers never need anything beyond what’s already in their house.

The Signs You Might Need More

There are pretty clear indicators that your electrical setup isn’t cutting it. Breakers that trip regularly are the obvious one. If you can’t run your table saw and dust collector at the same time without killing power to half the garage, that’s a problem.

Equipment that struggles to start or runs weaker than it should is another red flag. Motors that labour during startup, lights that dim noticeably when big tools kick on, or equipment that just doesn’t perform the way it should – these all point to capacity issues.

The really frustrating situation is when you can’t use multiple tools together. Maybe your compressor kicks on while you’re welding and everything shuts down. Or you can’t run your dust collector while using the planer. Having to choreograph your work around electrical limitations gets old fast.

What Drives the Need for Different Power

The type of work you’re doing matters more than the size of your space. A woodworker running professional-grade machinery all day needs different electrical capacity than someone doing occasional hobby projects. A metal fabricator with welding equipment, grinders, and plasma cutters has different demands than a pottery studio.

Multiple large motors running simultaneously pushes electrical systems hard. One big tool at a time usually works fine, but add a second or third and things get complicated. Commercial or industrial equipment brought into home settings often expects more robust power than residential setups provide.

Business use changes the equation too. If you’re running a legitimate business from home, downtime from electrical issues costs money. Equipment that relies on consistent power to produce quality work needs stable electrical supply. The occasional hobby project can tolerate some inconvenience, but a business really can’t.

The Practical Side of Upgrades

Here’s what most people don’t realize – upgrading electrical capacity isn’t always straightforward or cheap. Adding circuits might be simple if your main panel has spare capacity and you’re just splitting loads better. But if you need more total capacity or different power configurations, costs climb quickly.

Distance matters too. A workshop right next to your main electrical panel is one thing. A shed at the back of the property is another. The further power needs to travel, the more complicated and expensive installation becomes.

Some areas have restrictions on what’s available residentially. Not every property can get three-phase power even if you want it and can afford it. Power companies have guidelines about what they’ll connect to residential addresses, and those vary by location and existing infrastructure.

Making Smart Decisions

The smartest approach is starting with what you’ve got and seeing how it handles your actual needs rather than theoretical ones. Many people discover their existing power works better than expected once they organize their workflow around it.

If you’re buying equipment, consider what’s designed for residential use rather than industrial applications. Manufacturers make plenty of serious, high-quality tools that work on standard home power. Sometimes spending a bit more on equipment that suits your electrical situation beats spending thousands on electrical upgrades.

Think about usage patterns too. Staggering when you run different equipment, using smaller tools for less demanding tasks, and avoiding running everything simultaneously can stretch existing capacity surprisingly far. It’s not as convenient as unlimited power, but it works.

When to Get Professional Advice

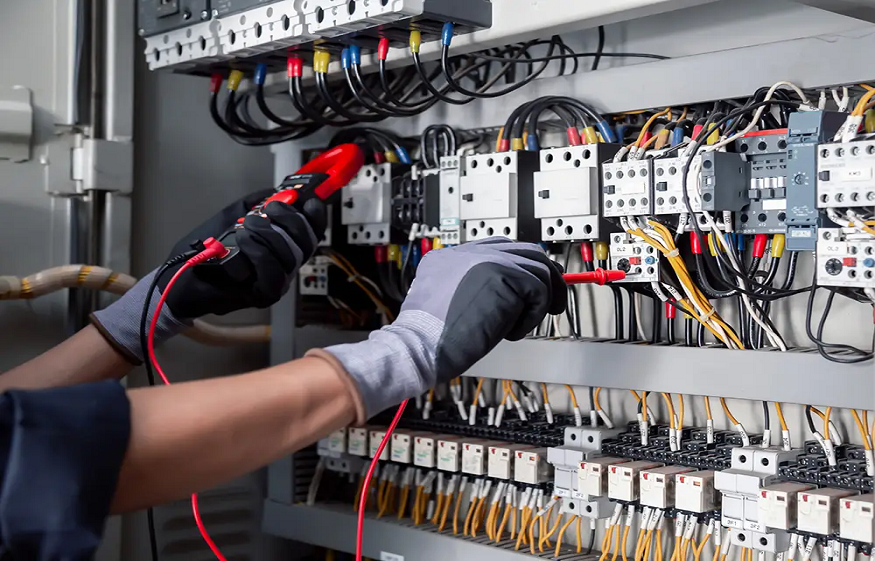

Some situations clearly need expert input. If you’re consistently tripping breakers, if equipment isn’t running properly, or if you’re planning significant expansions, talk to someone who knows electrical systems. A qualified electrician can assess what you’ve got, what you need, and what options actually make sense for your situation and budget.

They can also spot safety issues that non-experts miss. Overloaded circuits aren’t just annoying – they’re potential fire hazards. Equipment running on inadequate power can damage itself or create dangerous situations. Getting proper advice early saves money and problems later.

The Bottom Line

Most home workshops and studios run fine on standard residential power with some planning and realistic expectations. The key is matching your setup to your actual needs rather than worst-case scenarios or theoretical maximums that rarely happen.

Understanding your equipment’s real demands, how you’ll actually use your space, and what your existing electrical system can handle makes the difference between a functional workshop and an expensive mess of upgrades you didn’t need. Start simple, see what works, and upgrade only when actual problems rather than imagined ones demand it.

The goal is getting work done, not having the most impressive electrical setup. Sometimes the best power solution is the one you’ve already got – you just need to use it smartly.

Leave a Reply

You must be logged in to post a comment.